Description

Send Inquiry

| Pigment content: | 10% 15% 20% 25% 30% 35% 40% 45% 50%.. |

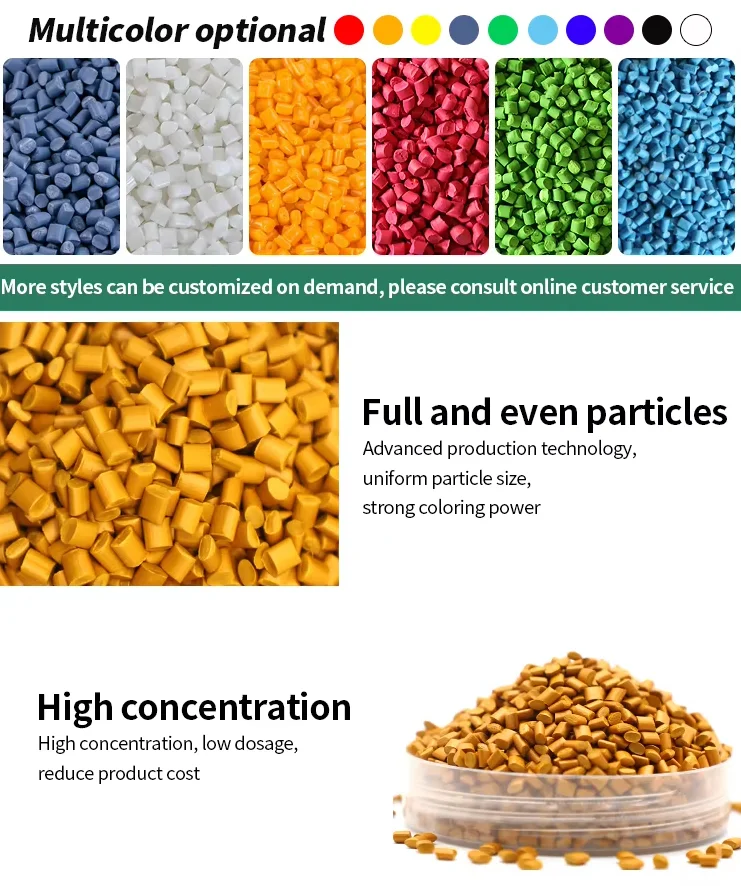

| Colour: | Red, Blue, Orange, Yellow, Green, Bright Red, Dark Blue, Sky Blue.. |

| Light and weather resistance: | Grade 4–8 |

| Melt index: | 21.6KG/200°C:1–30g/10min |

| Melting point: | 140°C–300°C |

| Phase fusibility: | ABS |

| Pellets/Granule diameter (mm): | 1.5–2.5 |

| Tinting Strength: | 95–105% |

Packaging & Shipping

- Packaging: 25 kg per bag (PE or kraft paper with inner liner).

- Storage: Store in a cool, dry, and ventilated area, away from direct sunlight and moisture.

- Shelf Life: 12 months under proper storage conditions.

- Shipping: Standard export packaging; customizable palletizing and labeling available.

- Delivery Time: 7–15 working days after order confirmation.

After-Sales Service

- Professional technical support for product application and color matching.

- Free sample testing and performance evaluation.

- Fast response within 24 hours for customer inquiries.

- Replacement or refund for confirmed quality issues.

- On-site or online training available for large-volume clients.