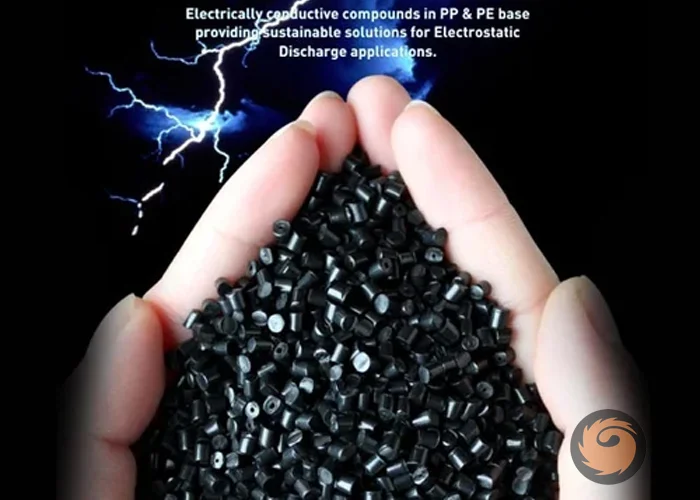

A conductive carbon black masterbatch is a specialized formulation used in the plastics and polymer processing industry to impart electrical conductivity, electrostatic discharge (ESD) protection, and antistatic properties to otherwise non-conductive polymer materials. It is created by dispersing conductive carbon black particles into a carrier resin at high concentrations, producing a concentrated compound that can be diluted into various thermoplastics during processing.

1. Composition

- Conductive Carbon Black: A type of carbon black with high structure, high surface area, and low resistivity. Its unique morphology enables the formation of a percolated conductive network within the polymer matrix.

- Carrier Resin: The polymer base (e.g., PE, PP, PS, ABS, PVC, PA, etc.) chosen to be compatible with the target plastic system. This ensures uniform dispersion and easy processing.

- Additives (optional): Dispersing agents, stabilizers, or processing aids to improve uniformity, reduce agglomeration, and optimize flow characteristics.

2. Functionality

The masterbatch introduces electrical pathways within the polymer once the loading level of carbon black reaches the percolation threshold (the point where enough conductive particles form an interconnected network). Key functionalities include:

- Electrical Conductivity: Reduces electrical resistance of the plastic, allowing static charge dissipation.

- Antistatic Properties: Prevents buildup of static electricity that could damage sensitive components or attract dust.

- Electrostatic Discharge (ESD) Protection: Ensures that charge does not accumulate to dangerous levels, protecting electronic devices and circuits.

- Electromagnetic Interference (EMI) Shielding: In certain applications, conductive plastics block or reduce electromagnetic radiation.

3. Advantages

- Cost-Effective: Easier and more economical to use than metal fillers or conductive polymers.

- Lightweight: Provides conductivity without adding significant weight, unlike metals.

- Versatility: Compatible with a wide range of thermoplastics.

- Processability: Supplied as pellets, making dosing, handling, and dispersion during extrusion, injection molding, or blow molding simple.

- Durability: Stable conductive performance over time, with good resistance to wear, heat, and environmental factors.

4. Applications

Conductive carbon black masterbatch is widely used across industries where static control or conductivity is critical:

-

Electronics & Electrical:

- ESD-safe packaging (trays, carriers, containers, films)

- Wire & cable jacketing for conductivity and shielding

-

Automotive:

- Fuel system components (pipes, tanks) to prevent static discharge

- Battery casings and connectors

-

Industrial:

- Conductive flooring, conveyor belts, and rollers

- Industrial containers for flammable or explosive materials

-

Consumer Goods:

- Antistatic housings for appliances, office equipment, or gadgets

- Films and sheets requiring dust-repellent surfaces

5. Performance Considerations

- Loading Level: The dosage of masterbatch determines the final resistivity range (antistatic, static dissipative, or conductive).

- Dispersion Quality: Uniform dispersion is critical to achieving consistent conductivity. Poor dispersion leads to hotspots or insulation zones.

- Polymer Compatibility: The carrier resin must be compatible with the base polymer to ensure proper processing.

- Processing Conditions: Extrusion, injection molding, or blow molding parameters affect the conductive network stability.

✅ In summary: A conductive carbon black masterbatch is a highly engineered additive solution designed to transform insulating plastics into materials capable of dissipating static charges, conducting electricity, or shielding against EMI. Its balance of performance, cost-efficiency, and versatility makes it indispensable in electronics, automotive, packaging, and industrial applications where safety, reliability, and performance are essential.