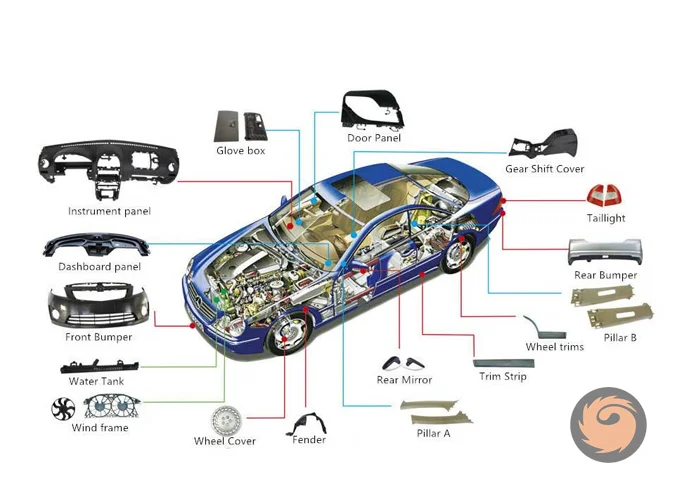

Here are the automotive parts where color masterbatch is most often used:

Interior Parts

- Dashboard panels and instrument clusters – require uniform matte or glossy finishes with UV stability.

- Door panels and trims – colored or textured plastics matched with the interior theme.

- Center consoles and gear shift surrounds – premium look achieved with color and effect pigments.

- Pillars, headliners, and glove boxes – use of color masterbatch ensures consistency across molded parts.

- Seats (plastic frames, covers, and adjustment knobs) – durable, scratch-resistant colors.

- Air vents and HVAC components – matte black or customized colors for integration.

Exterior Parts

- Bumpers and bumper trims – colored masterbatch is used to match or contrast with the body paint.

- Grilles and exterior trims – especially black masterbatch for high gloss or matte finishes.

- Side mirrors and door handles – high UV resistance to prevent fading.

- Roof rails and spoilers – lightweight parts often colored with masterbatch instead of paint.

Lighting & Functional Parts

- Headlamp and taillamp housings – often black, gray, or metallic-effect masterbatches.

- Interior lighting covers – transparent or translucent masterbatch for diffusion and tinting.

- Signal light covers – orange/red masterbatches for compliance with regulations.

Under-the-Hood & Technical Components

- Battery casings – usually black masterbatch with carbon black for UV stability.

- Fluid reservoirs and caps – color coding with masterbatch (blue for washer fluid, yellow for brake fluid, etc.).

- Wire and cable insulation – color masterbatch for identification and heat resistance.

? In short: dashboards, door trims, bumpers, grilles, lamp housings, and battery casings are the automotive parts where color masterbatch is used most often, with black masterbatch being the dominant one due to UV stability and aesthetics.