-

What are the advantages of using color masterbatch for polymers?

color masterbatch for polymers offers enhanced color consistency, ease of handling, cost savings, customization, improved quality, environmental safety, and processing efficiency, making it a valuable choice across multiple industries. -

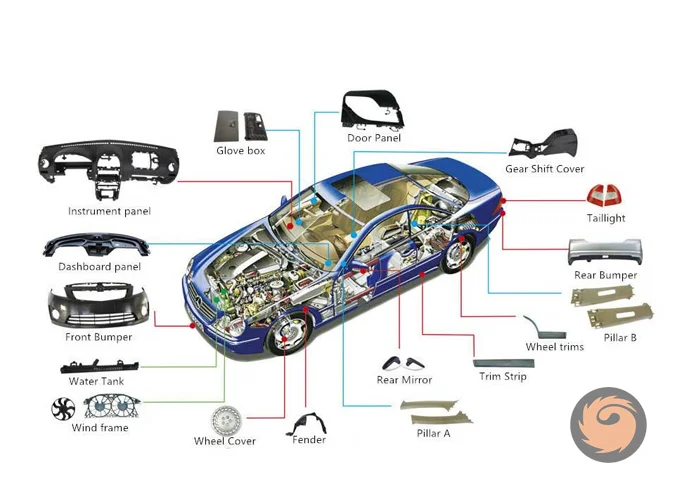

Which automotive parts use color masterbatch most often?

Bumpers, mirrors, dashboards, trims, lighting covers, and some under-hood components as the primary automotive parts utilizing color masterbatch extensively. -

What is color masterbatch used for in the automotive industry?

Color masterbatch in the automotive industry is primarily used for coloring and enhancing the aesthetic appeal of various vehicle parts, both interior and exterior. It provides consistent, vibrant, and uniform colors for components like bumpers, mirrors, door handles, dashboards, body panels, trims, and lighting housings. -

How are medical grade color masterbatches different from standard masterbatches?

the key distinctions lie in stringent safety compliance, biocompatibility, precise color coding, and material suitability needed for medical grade masterbatches versus broader functional color and additive use in standard masterbatches. -

Are medical grade color masterbatches REACH and RoHS compliant?

Yes, medical grade color masterbatches can be formulated to be both REACH and RoHS compliant. -

Middle east & africa color masterbatch market

The Middle East & Africa (MEA) color masterbatch market is experiencing steady growth,other sources estimate a slightly higher CAGR of around 6.1% to 6.35% into the early 2030s, with the market potentially reaching near USD 2.65 billion by 2030 and around USD 1.6 billion by 2031 depending on the scope considered specifically for color masterbatch or overall masterbatch markets. -

Color masterbatch HS code

the primary HS codes for color masterbatch typically fall under 3206.19 and 3206.49, with subheadings like 32064900 or 320649900 being common in trade classifications. -

What is the difference between pigment and master batch?

pigments are raw coloring powders, while masterbatches are advanced, pelletized color concentrates containing pigments and additives in a polymer carrier, designed for optimized coloring performance and handling in polymer manufacturing processes. -

What is color master batch?

A color masterbatch is a concentrated mixture of highly pigmented plastic pellets used to color plastics during manufacturing. These pellets cannot be used by themselves for molding but are mixed with uncolored plastic pellets to impart specific colors to the final product. The masterbatch consists of colorants (such as organic dyes, organic or inorganic pigments), a polymer-specific carrier resin, dispersing agents, and additives. The pigments are uniformly distributed in the polymer carrier through heat treatment and mixing, then pelletized for use. -

What is white filler masterbatch used for?

White filler masterbatch is widely used in industries like packaging, automotive, construction, textiles, and consumer goods to improve the appearance, performance, and durability of plastic products while managing production costs efficiently. It also facilitates easier processing and uniform dispersion in the base polymer during manufacturing. -

Is food grade white masterbatch compliant with FDA standards?

Yes, food grade white masterbatch can be FDA-compliant, provided that:Titanium dioxide and all other additives meet FDA regulatory standards.The carrier resin is FDA-approved for the intended food contact type.The final plastic article passes FDA migration and usage condition requirements. -

What industries use food grade white masterbatch?

Food grade white masterbatch is primarily used in industries that require safe and high-quality plastic packaging for food and pharmaceuticals, as well as in the production of household goods and medical devices. Specifically, it's used in food packaging (containers, bottles, bags), pharmaceutical packaging, and for household items like appliances and containers. It's also used in medical devices due to its biocompatibility and regulatory safety. -

What is the difference between PE white masterbatch and PP white masterbatch?

The key difference between PE white masterbatch and PP white masterbatch lies in their carrier resins: PE masterbatch uses polyethylene (PE) as the base, while PP masterbatch uses polypropylene (PP). This difference in carrier resin impacts the masterbatch's compatibility with different base polymers and its suitability for various applications. -

What is PP white masterbatch?

PP (polypropylene) white masterbatch is a concentrated blend of titanium dioxide (TiO2) pigment and a PP carrier resin, used to impart a bright white color and opacity to polypropylene products. It's a convenient and efficient way to achieve a desired white shade in various plastic applications like films, injection molding, and fibers. -

What is PE white masterbatch?

PE white masterbatch is a concentrated mixture of titanium dioxide (TiO2) pigment dispersed in polyethylene (PE) resin. It's a widely used additive in plastic manufacturing to impart a bright white color and increase the opacity of various plastic products. This masterbatch is a cleaner and more efficient way to whiten plastic compared to using raw pigments or powders. -

Why does white PET masterbatch yellow at 180°C?

White PET masterbatch yellowing at 180°C is mainly caused by heat-induced oxidation, impurities, and the quality of additives like titanium dioxide. To prevent yellowing, it is important to use high-purity TiO₂, add UV stabilizers and antioxidants, control processing temperatures, and avoid impurities. Specialized additives and proper storage also help maintain whiteness and minimize discoloration during PET processing. -

Is white single pigment masterbatch UV resistant?

Yes, white single pigment masterbatch, which typically uses titanium dioxide (TiO₂), is generally considered UV resistant. TiO₂ is known for its high opacity, brightness, and resistance to UV radiation, making it a suitable choice for applications requiring UV protection. While the masterbatch itself provides UV resistance, it's also common to incorporate additional UV-stabilizing additives for enhanced performance in outdoor applications, according to some masterbatch manufacturers. -

What is white master batch?

White masterbatch is a concentrated mixture of titanium dioxide (TiO₂) and polymer carrier resin, sometimes enhanced with additives, that is used to impart opacity, brightness, and whiteness to plastic products. It is manufactured by dispersing a high loading of TiO₂ pigments—usually ranging from 20% up to 75%—into a compatible polymer base such as polyethylene (PE), polypropylene (PP), polystyrene (PS), or other resins. The dispersion process ensures that the TiO₂ particles are evenly distributed at a microscopic level, which provides excellent coverage and color consistency when blended with raw polymer materials.