-

What does PPA masterbatch do in plastics

The primary function of PPA masterbatch is to enhance the mechanical, thermal, and chemical performance of plastics. -

How is FEP masterbatch used in plastics?

FEP masterbatch is used in plastics primarily as a functional additive or colorant to impart the unique properties of FEP (fluorinated ethylene propylene) resin to various plastic products. It offers excellent chemical resistance, high temperature tolerance, electrical insulation, and mechanical strength, making it suitable for demanding applications. -

Blue masterbatch in plastics:types,functions,and advantages

Blue masterbatch in plastics is a concentrated mixture of blue pigments, carrier resin, and additives used to impart a vibrant blue color and improve the properties of plastic products. The types of blue masterbatch vary mainly based on the carrier resin and additives used, tailored for compatibility with different plastic materials like polyethylene, polypropylene, polystyrene, and PVC. -

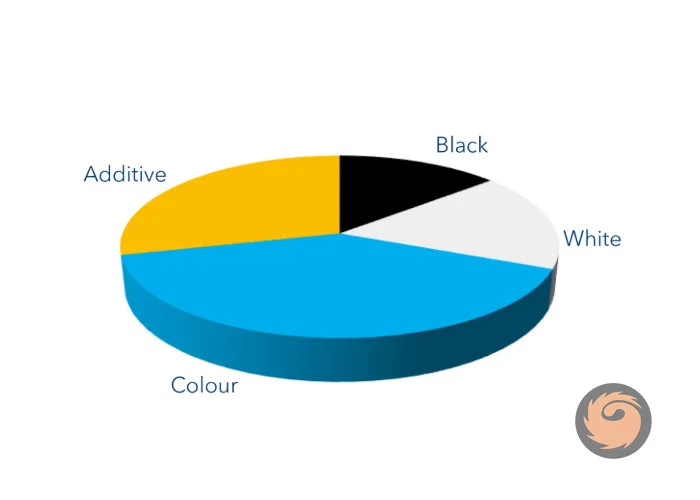

Plastic masterbatch:definition,types,and applications

Discover plastic masterbatch: a concentrated mixture of pigments and additives that enhances color, performance, and functionality in plastics. Learn about types, applications, and benefits across packaging, automotive, construction, and consumer goods. -

How is masterbatch added to plastic

Masterbatch is added to plastic through a dosing and mixing process during plastic manufacturing. Here’s how it typically works: -

Carbon Black Masterbatch: A Comprehensive Guide

Carbon Black Masterbatch guide: types, manufacturing process, applications, and benefits to enhance color, durability, and performance in plastics. -

What is a masterbatch?

Masterbatch is a concentrated mixture of pigments, additives, and a polymer base, used to color and enhance the properties of plastic products. It's essentially a pre-compounded material that is added to a base polymer during manufacturing to achieve desired color or functional characteristics. -

what is silicone masterbatch?

Silicone masterbatch is a concentrated form of silicone (siloxane) polymers, acting as an additive in thermoplastics to improve their processing, surface quality, and performance. Key benefits include improved fluidity, reduced friction and wear, better mold release, and enhanced thermal stability. It is used in industries like automotive, electrical, and construction to create more efficient, durable, and high-performing plastic and rubber products. -

What is a light diffuser masterbatch

A light diffuser masterbatch is a concentrated additive, or "masterbatch," of particles like barium sulfate dispersed in a polymer carrier that is added to transparent plastics to scatter and diffuse harsh, concentrated light into a softer, more even glow without significantly reducing light transmission. It eliminates glare and hot spots, creating a uniform and comfortable light distribution for applications such as LED light panels, agricultural films, and automotive lighting. -

What is defoaming masterbatch used for in plastics?

Defoaming masterbatch is used in plastics, especially recycled plastics, to absorb moisture and prevent defects like bubbles, moire, cracks, and spots that occur during processing. By adding this masterbatch, manufacturers can eliminate the need to pre-dry raw materials, reducing energy consumption, labor, and overall production costs while improving the quality and appearance of the final product. -

What are the benefits of using anti fog additive masterbatch?

Anti-fog additive masterbatch benefits include preventing condensation, which maintains perfect transparency and visual appeal in food packaging, extends shelf life, and boosts crop yield in agricultural films by enhancing light transmission. The additives reduce water surface tension, causing droplets to form a thin, uniform layer instead of obscuring fog, ensuring product visibility and preventing spoilage from moisture. -

What is anti fog masterbatch?

Anti fog masterbatch is a concentrated mixture of anti-fogging agents and a base polymer, typically polyethylene or polypropylene, used in plastic film production to prevent the formation of water droplets (fog) on the film's surface. This masterbatch works by migrating to the film's surface and lowering the surface tension of water, causing it to spread into a thin, transparent film instead of forming visible droplets. Its primary applications are in food packaging, where it preserves product visibility and freshness, and in agricultural films, where it improves light transmission and protects plants from condensation damage. -

Additive masterbatch market

The global additive masterbatch market was valued between USD 2.79 billion and USD 3.5 billion in 2024 and is projected to grow to approximately USD 4.21 billion to USD 4.9 billion by 2030-2032, at a CAGR of around 5.7% to 5.9%. Growth is driven by the demand for enhanced plastic properties, such as UV resistance and flame retardancy, in sectors like packaging, automotive, and consumer goods. -

What is filler masterbatch?

Filler masterbatch is a concentrated mixture of inorganic fillers, additives, and a polymer carrier resin. It is designed to be blended with raw polymers during processing to reduce material costs, enhance mechanical properties, and improve processing performance. -

What is a laser marking additive masterbatch

A laser marking additive masterbatch is a concentrate added to plastics to enable or improve laser marking by changing the plastic's properties to react to a laser beam, creating a clear, durable mark. These additives absorb laser light, converting it to heat that discolors, melts, or gasifies the material's surface to form text or designs. They are essential for marking dark plastics with light marks (like white text on black) or enhancing contrast on various plastic types for products like electronics, packaging, and cables. -

What are antiblock additives in plastics?

Learn about antiblock additives in plastics – their types, functions, applications, and benefits. Prevent film sticking, improve processing, and enhance clarity with inorganic and organic antiblock solutions. -

What is a PVC additives masterbatch

A PVC additives masterbatch is a highly concentrated blend of functional additives, colorants, and a carrier resin that is mixed with PVC during the manufacturing process to impart specific properties or colors to the final PVC product. These masterbatches improve the physical and chemical characteristics of PVC, such as its resistance to UV light or heat, its impact strength, or its flame retardancy, while also enabling precise and consistent coloring. They are typically supplied as pellets or granules, making them easy to dose and ensuring uniform dispersion of additives and pigments for higher process efficiency and product quality. -

What is recycled additive masterbatch

A recycled additive masterbatch is a specially formulated plastic masterbatch designed to improve the quality, performance, and processability of recycled plastics. It is made by compounding various functional additives (such as antioxidants, compatibilizers, dispersants, stabilizers, lubricants, or odor-removing agents) into a carrier resin, usually compatible with recycled polymers like PE, PP, or PET.