Description

Send Inquiry

How it Works

- Blocking: Plastic films can stick together due to Van der Waals forces between smooth surfaces.

- Microscopic Surface Roughness: The masterbatch contains additives like silica, talc, or waxes that create tiny, controlled bumps on the film's surface.

- Reduced Contact Area: These bumps increase the distance between layers, decreasing the actual contact area and preventing them from adhering.

- Improved Slip: Slip additives, often fatty acid amides, migrate to the surface to provide external lubrication, further reducing friction and allowing smooth sliding.

Benefits

- Prevents Blocking: Stops plastic films from sticking together during production, winding, and storage.

- Improves Film Handling: Makes films easier to unwind, stack, and process without damage.

- Reduces Friction: Enhances slip properties, making it easier for the film to slide over other surfaces.

- Maintains Clarity: High-performance additives provide anti-blocking properties without significantly affecting film transparency.

- Increases Durability: Contributes to the overall quality and durability of the final plastic product.

Packaging & Delivery

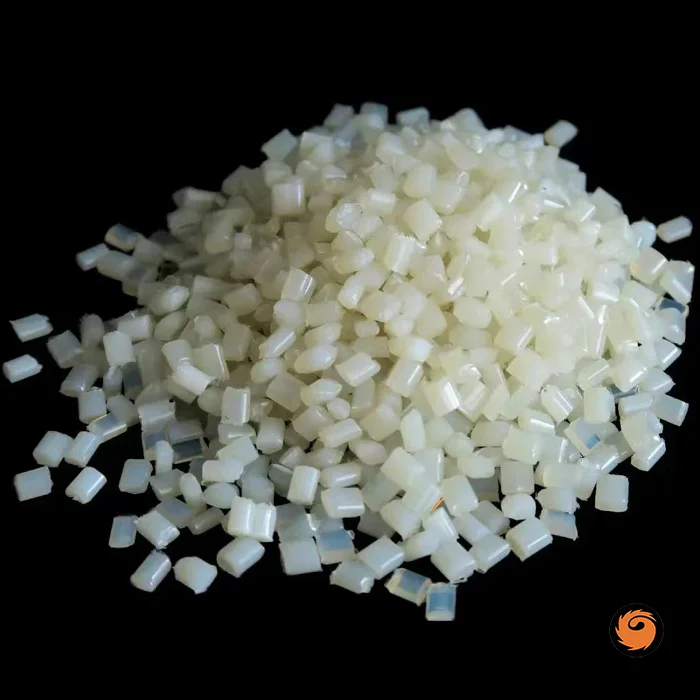

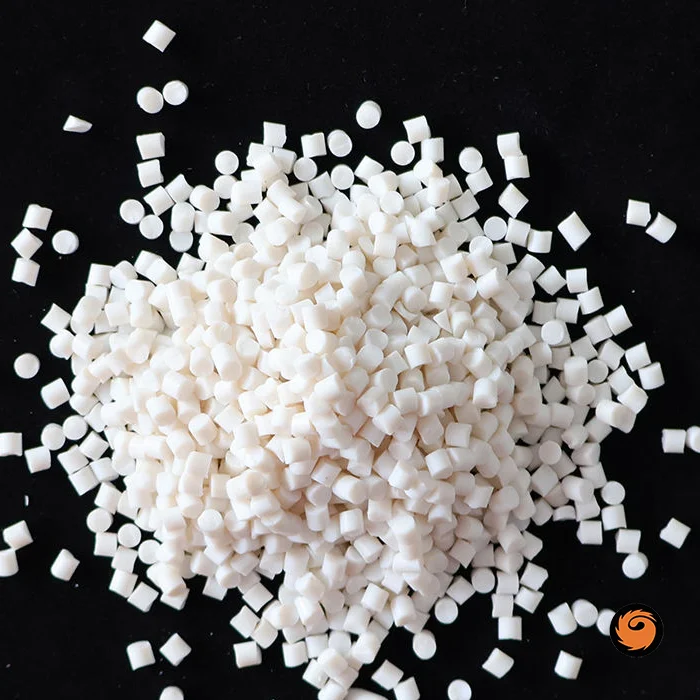

- Packaging Options: 25 kg moisture-proof PE bags with inner liner.

- Storage Conditions: Keep in a cool, ventilated, and dry place. Avoid direct sunlight and humidity.

- Delivery Lead Time: Standard delivery within 7–15 working days after order confirmation.

- Shipping Methods: Available by sea, air, or express based on customer requirements.