Technical Parameters

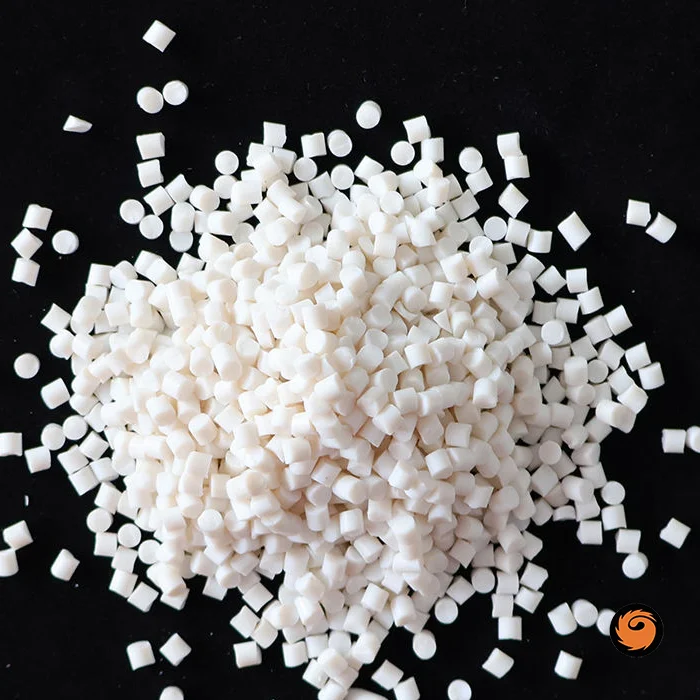

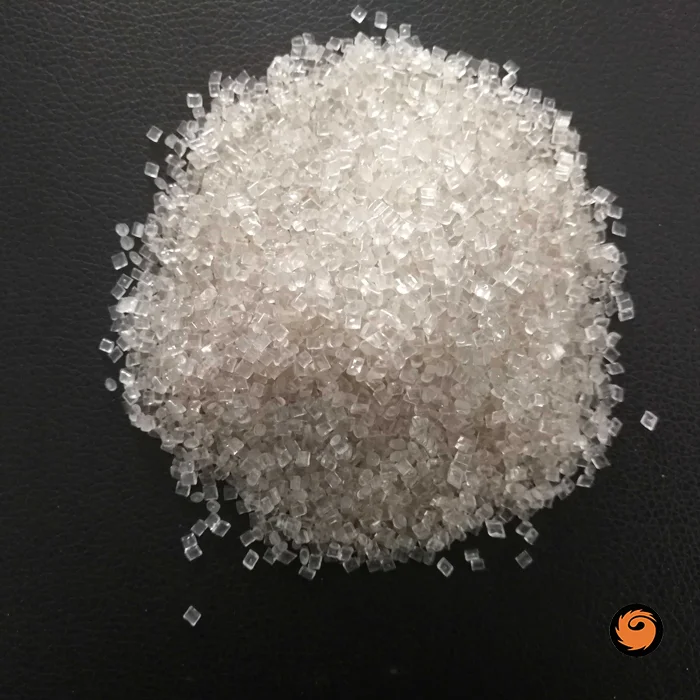

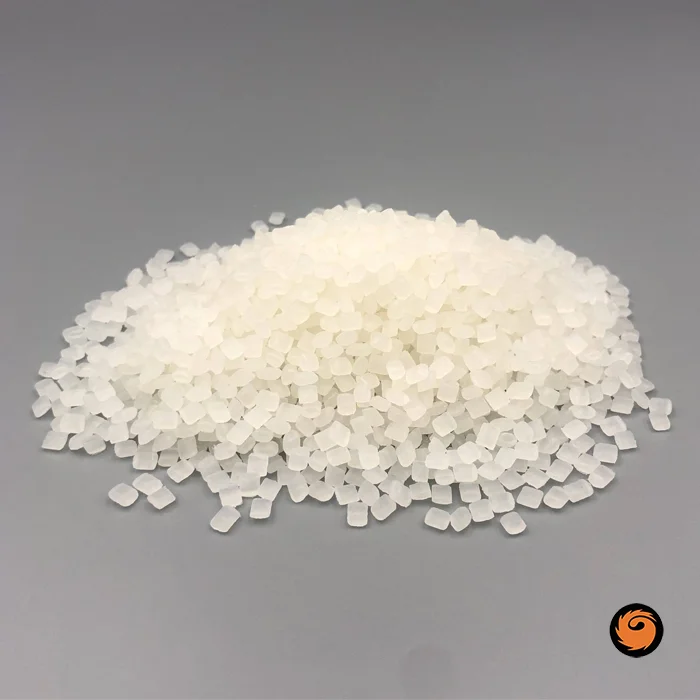

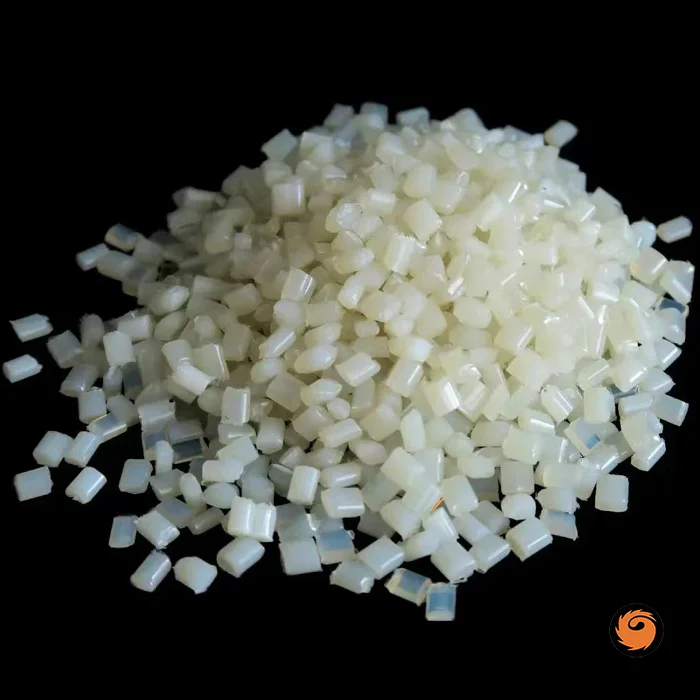

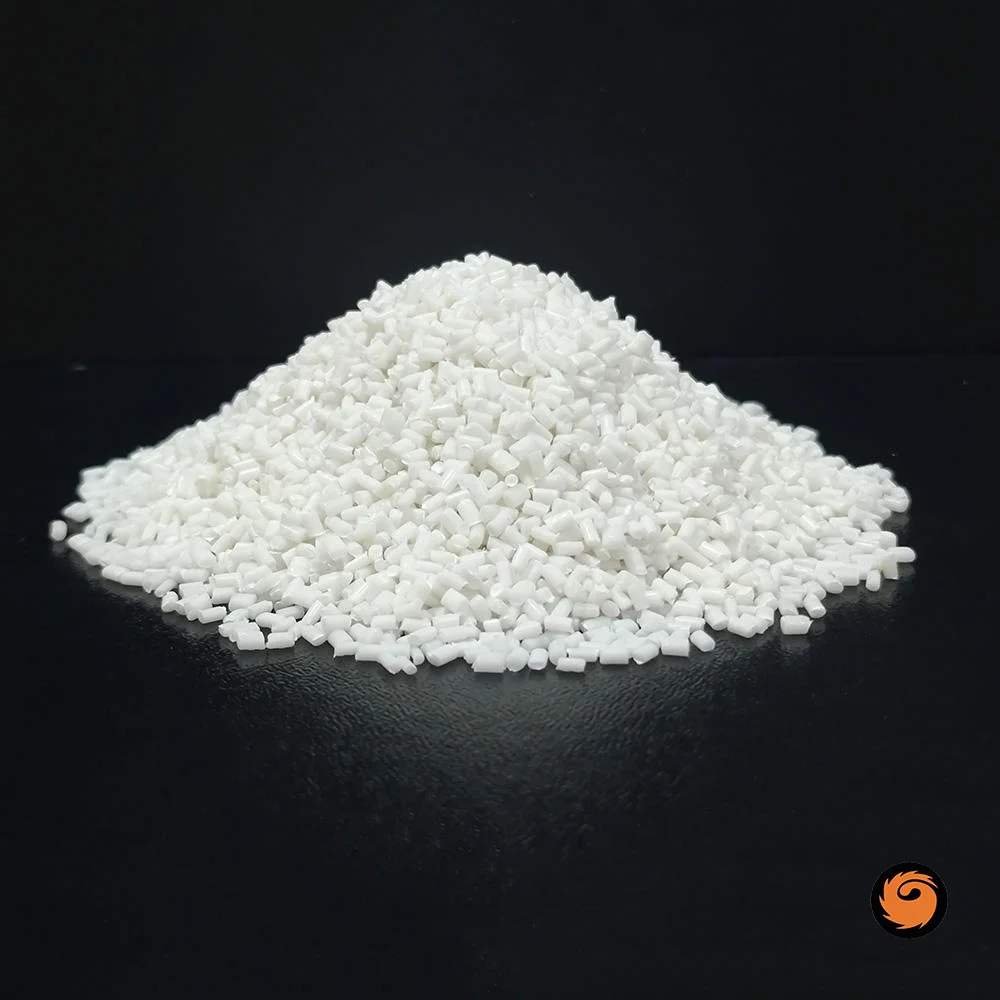

| Carrier | Virgin PE/PP |

| MFI (g/10min) | 10~45 |

| Moisture Content | ≤0.15% |

| Density | 0.96 g/cm³ |

| Weather/Light/Color Fastness | Level 4~8 |

| RoHS Index | Environment-friendly |

| Color Migration Resistance | Barely Dissolve Out |

| Packing | 25 kg/bags |

Packaging & Shipping

- Standard Packaging: 25 kg woven bag with inner PE liner.

- Custom Packaging: Available upon request.

- Shipping: Delivered via sea, air, or express courier. Ensures safe handling with moisture-resistant packaging.

After-Sales Service

- Technical support for dosage and processing.

- Free samples for testing and trial runs.

- Assistance with polymer compatibility and product optimization.

- Prompt response for quality issues or delivery concerns.

FAQ

Q1: Which polymers are suitable for optical brightener masterbatches?

A1: They are compatible with PP, PE, PS, PET, and other common thermoplastics.

Q2: What is the recommended dosage?

A2: Typically 0.01% to 0.3% of the polymer weight, depending on desired brightness.

Q3: Can it be used in high-temperature processing?

A3: Yes, the masterbatch is thermally stable and suitable for standard polymer processing temperatures.

Q4: Will it affect the color of pigments or other additives?

A4: It generally does not affect pigments and is compatible with most colorants.

Q5: Can you provide customized masterbatches?

A5: Yes, we offer tailor-made solutions for specific polymer types, brightness levels, or processing requirements.