| Carrier Resin | PP / PE |

| Active Ingredient Content | 10% – 50% (customizable) |

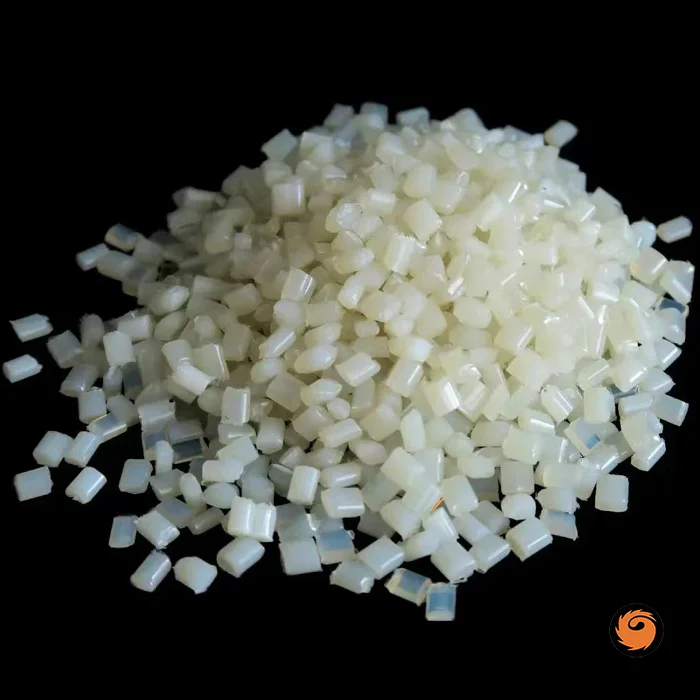

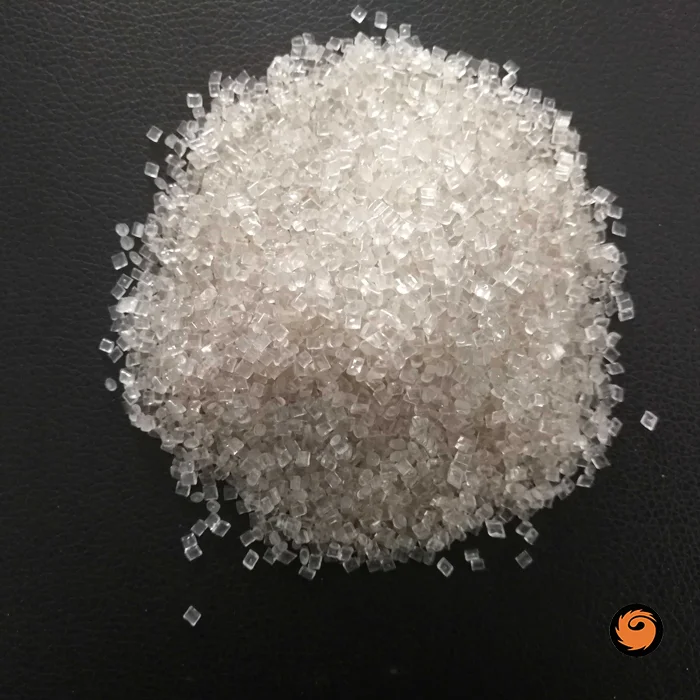

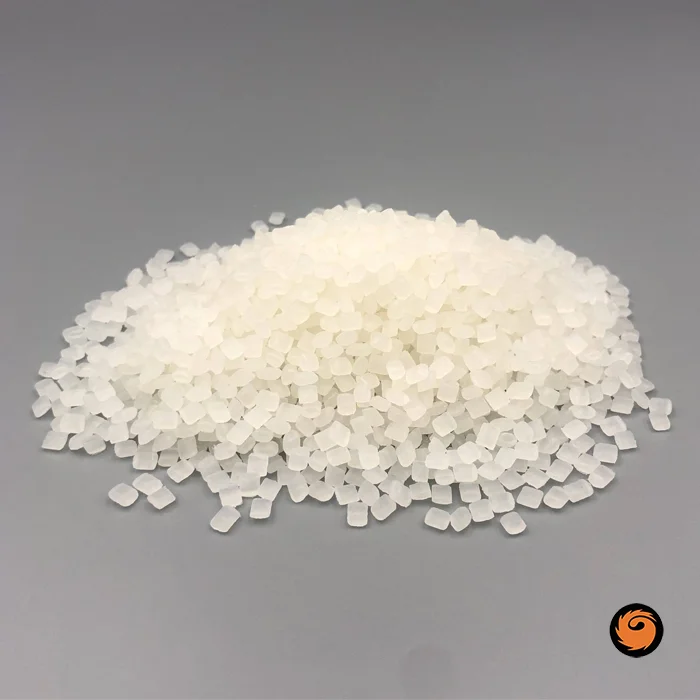

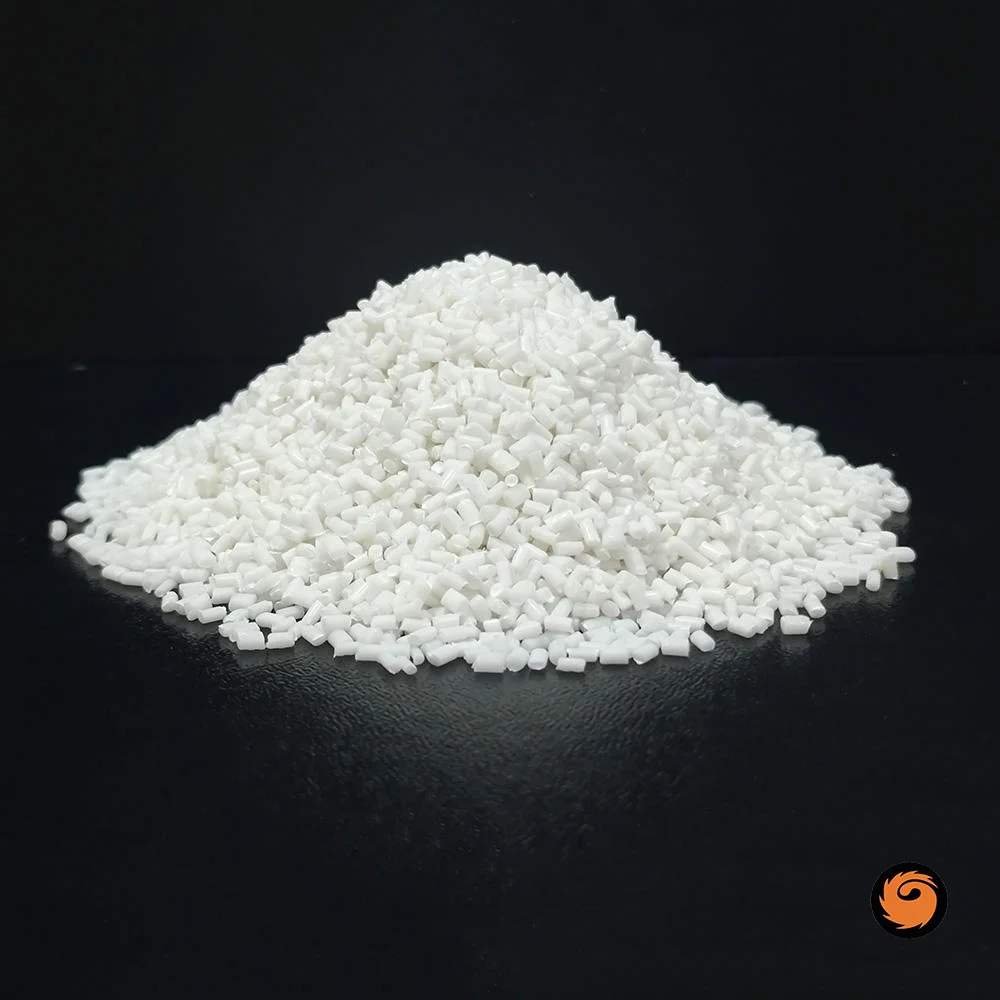

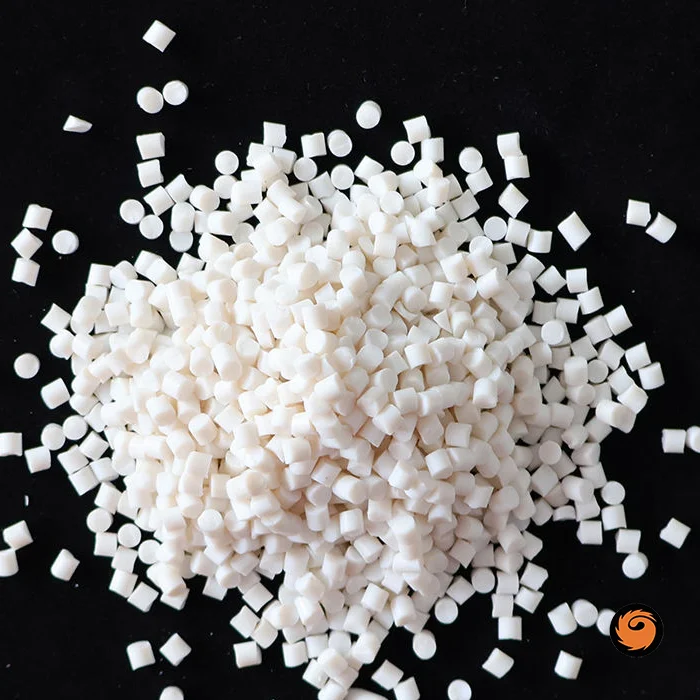

| Appearance | Pellets / Granules |

| Addition Ratio | 2% – 4% |

| Heat Resistance | Up to 300°C (depending on formulation) |

| Processing Method | Injection molding, extrusion, blow molding |

How it works:

- UV Absorption: UV absorbers convert UV radiation into heat, which is then dissipated without harming the plastic.

- Free Radical Scavenging: Hindered amine light stabilizers (HALS) capture free radicals that form during the degradation process, preventing them from breaking down the polymer's chemical bonds.

Key benefits:

- Extended Product Life: By protecting against photo-degradation, the masterbatch significantly increases the useful life of plastic items.

- Improved Appearance: It prevents discoloration and maintains the product's original color.

- Enhanced Mechanical Properties: The structural integrity and physical properties of the plastic are preserved.

- Cost Savings: By prolonging the life of products, replacement costs are reduced.

Common applications:

- Agriculture: Greenhouse films, mulch, crop covers, and woven sacks.

- Automotive: Components used in vehicle interiors, exteriors, and under the hood.

- Construction: Building materials, pipes, and profiles.

- Consumer Goods: Outdoor furniture, crates, drums, and water tanks.

- Packaging: FIBCs (flexible intermediate bulk containers) and other packaging films.

Packaging & Storage

Packaging: 25kg moisture-proof bags with inner PE liner.

Storage: Keep in a cool, dry place away from direct sunlight. Shelf life is 12 months when stored properly.