Technical Parameters

| Item | Specification |

|---|---|

| Active Ingredient | Inorganic / Organic Antimicrobial Agent |

| Carrier Resin | PE, PP, PET, PC, ABS, etc. |

| Addition Ratio | 2% – 5% (recommended) |

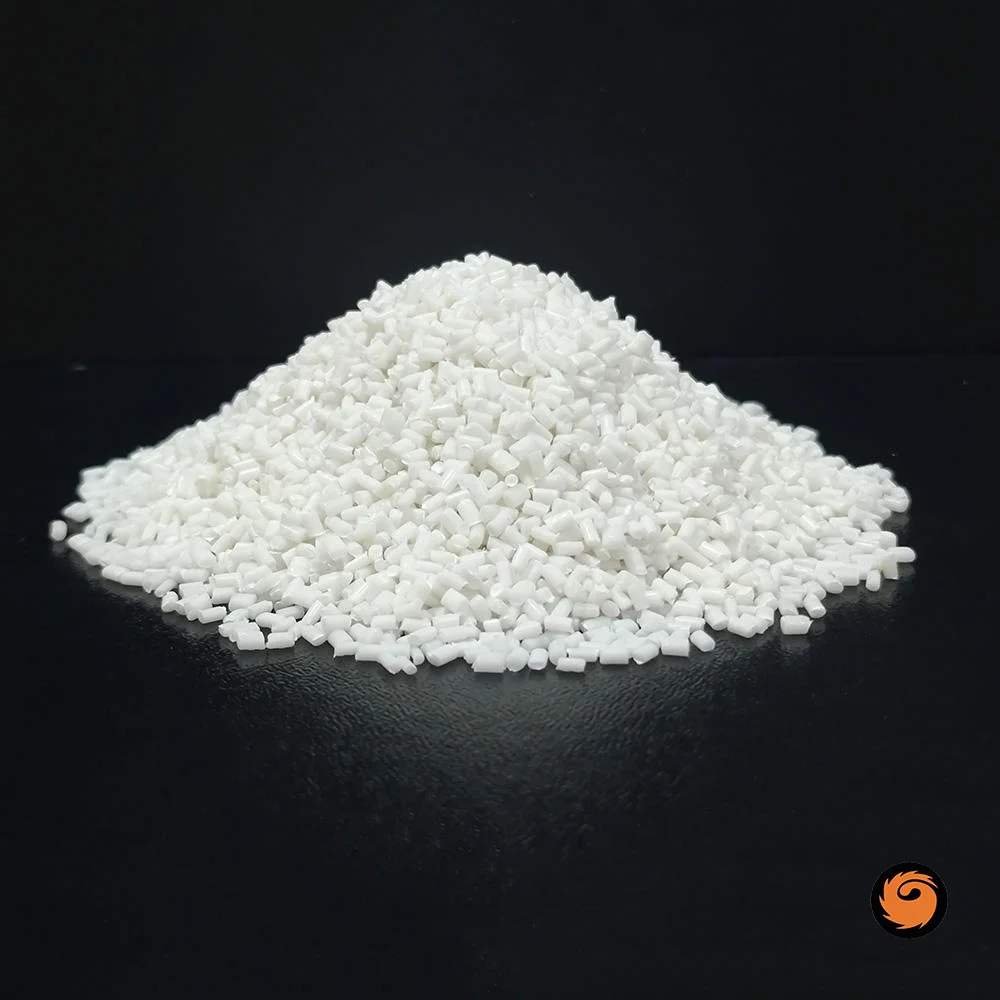

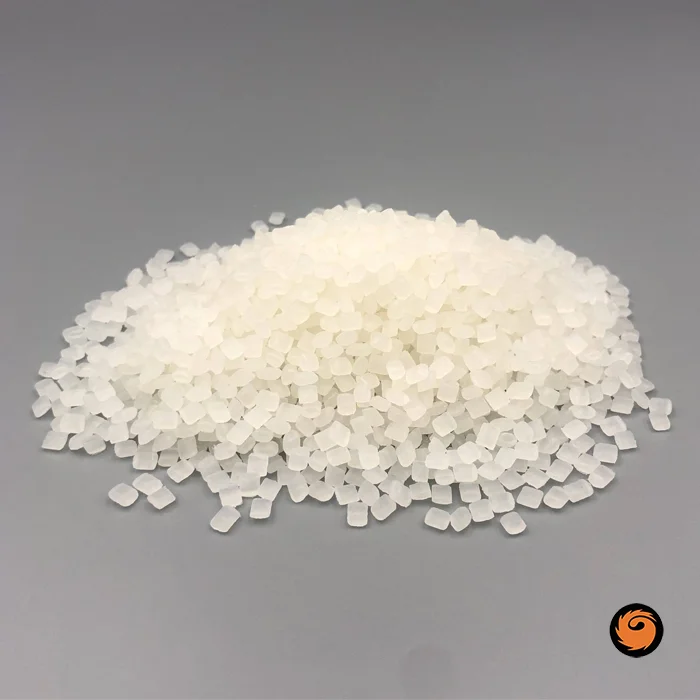

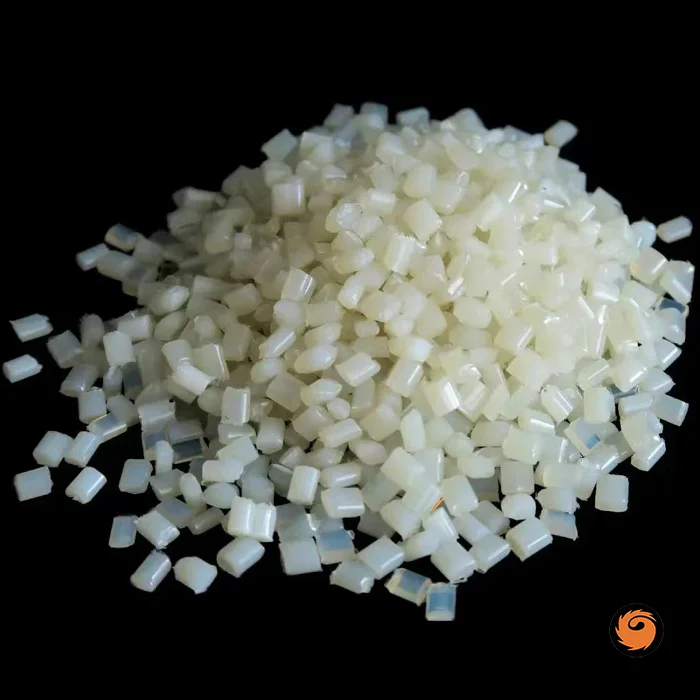

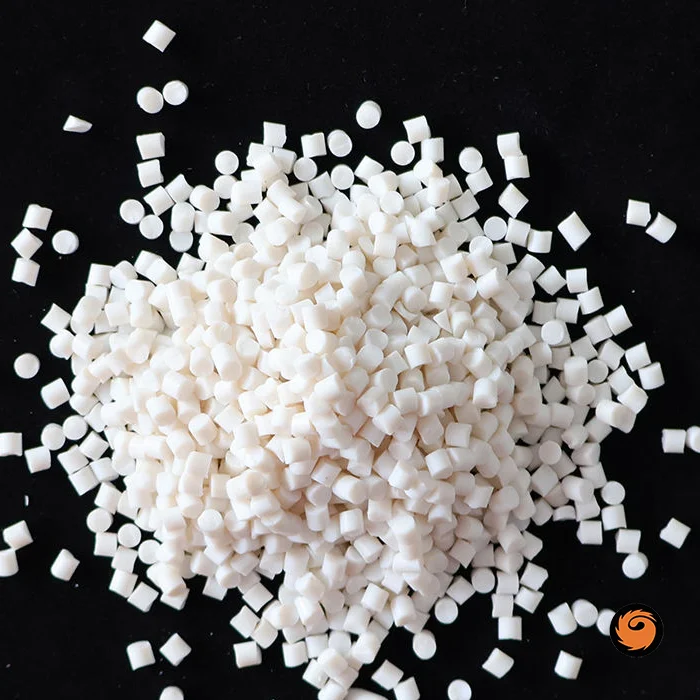

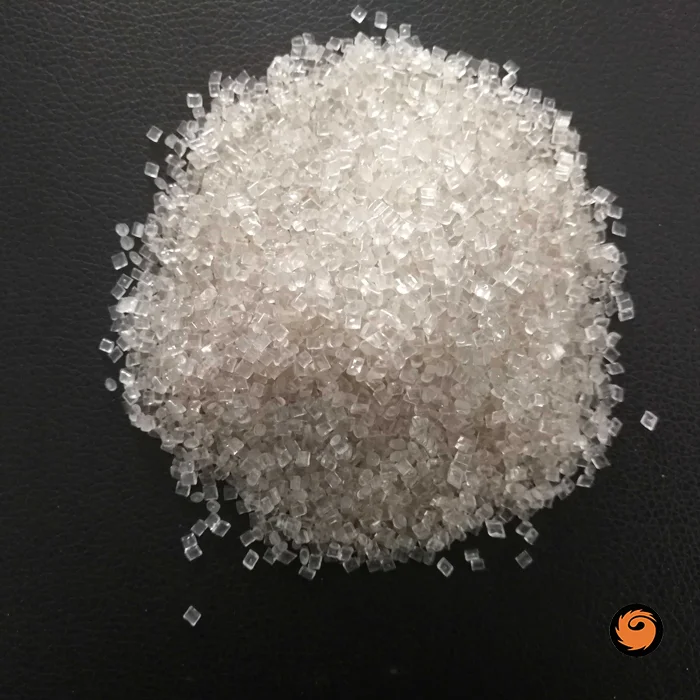

| Appearance | Granule / Pellet |

| Color Options | Natural, White, or Customized |

| Processing Temperature | 160°C – 300°C (depending on resin) |

| Certification | FDA, RoHS, REACH |

Packaging & Delivery

- Packaging: Standard 25 kg bags with moisture-proof lining.

- Delivery: Shipped by sea, air, or express according to customer requirements.

- Storage: Store in a cool, dry place away from direct sunlight; keep sealed to prevent moisture absorption.

After-Sales Service

- Technical support for processing and application guidance.

- Custom formulation service based on client product requirements.

- Prompt response to customer inquiries and feedback.

- Replacement or return policy for any quality-related issues.

FAQs

Q1: What is the typical addition ratio of antimicrobial masterbatch?

A1: The recommended addition ratio is 2%–5%, but it can be adjusted depending on the required antimicrobial performance and application.

Q2: Does the antimicrobial effect wear off over time?

A2: No, the antimicrobial agents are embedded in the polymer matrix, ensuring long-lasting performance throughout the product’s life cycle.

Q3: Is this masterbatch safe for food-contact applications?

A3: Yes, our antimicrobial masterbatch complies with FDA and EU food-contact safety regulations when specified.

Q4: Can it be used with all types of plastics?

A4: It is compatible with most thermoplastics such as PE, PP, ABS, PET, and PC. For special materials, customized solutions are available.

Q5: Do you provide customized formulations?

A5: Yes, we can tailor carrier resin, concentration, and color according to customer requirements.