Description

Send Inquiry

| Property | Typical Value |

|---|---|

| Carrier Resin | PP / PE |

| Talc Content | 80% Talc + 20% PP/PE |

| Addition Ratio | 4% – 10% |

| Processing Temperature | 180 – 250 °C |

| Particle Size of Talc | <5 μm |

| Melt Flow Index (MFI) | 10.0-45.0/Customized |

| Moisture Content | <0.1% |

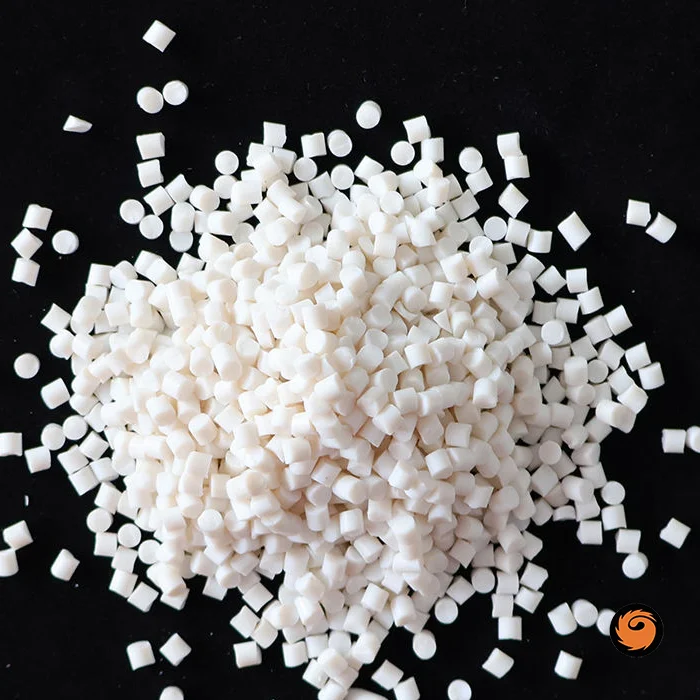

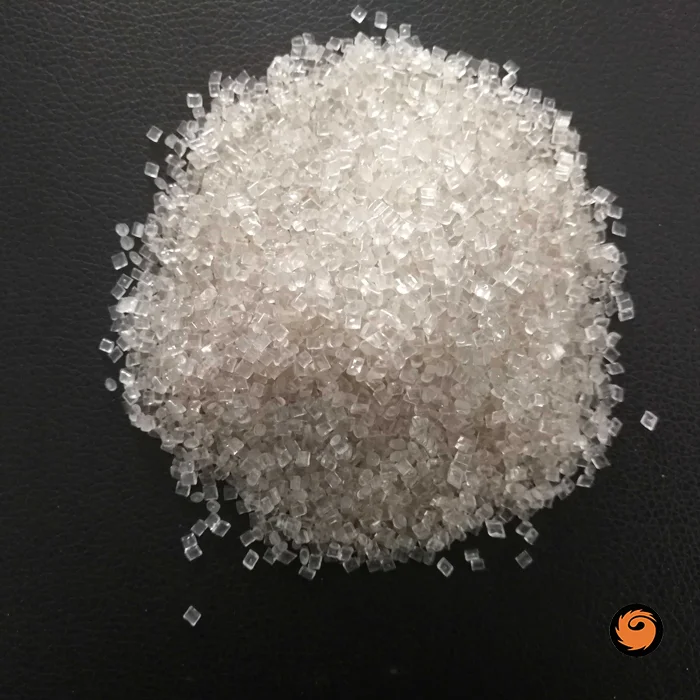

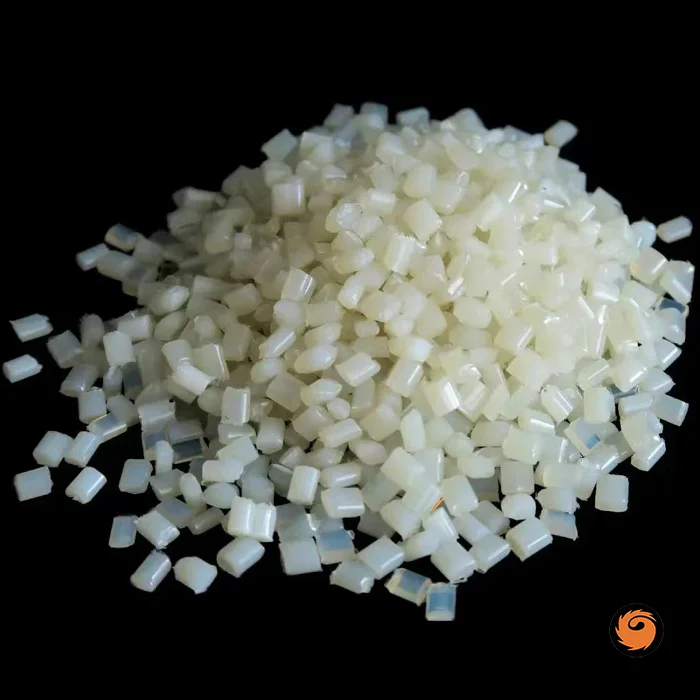

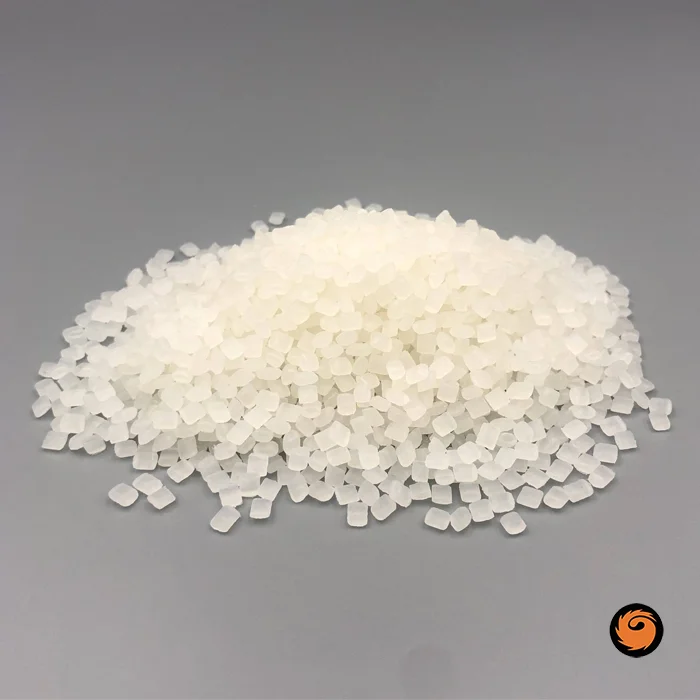

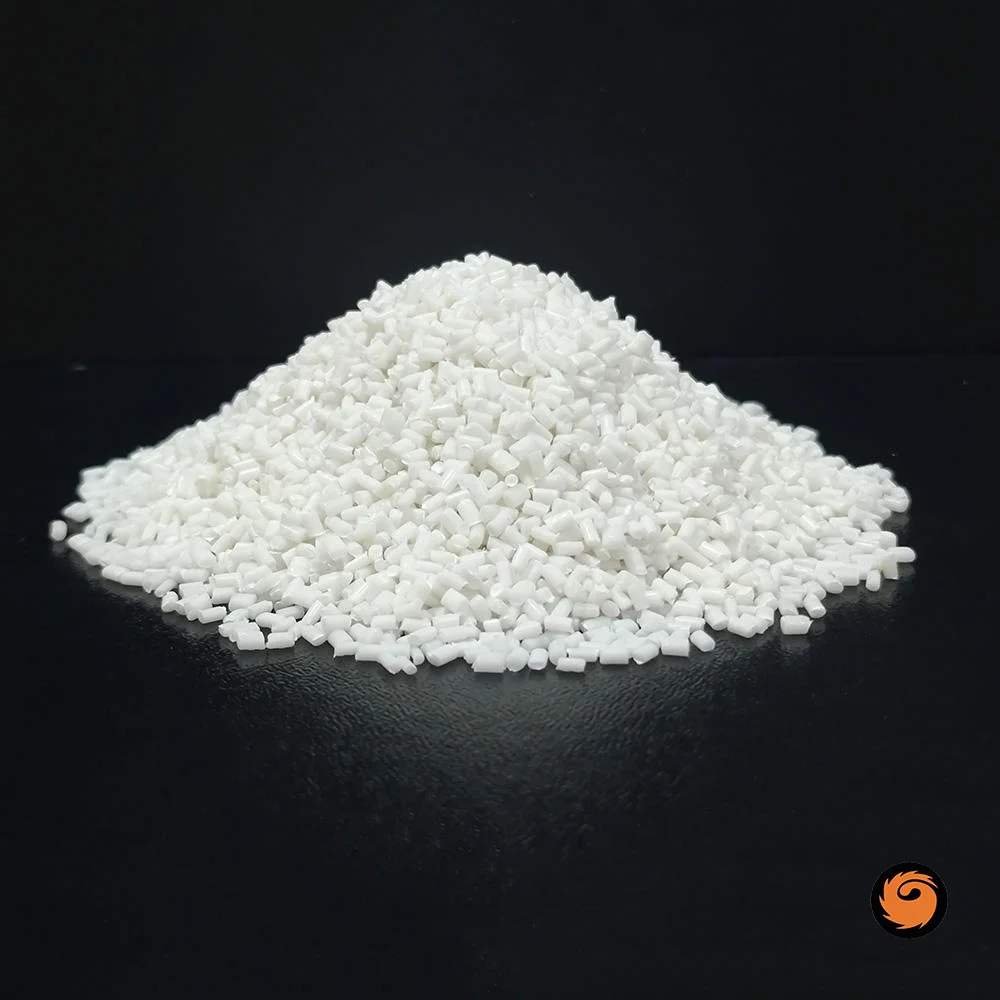

| Appearance | Light gray or white granules |

| Function / Application | Enhances the rigidity, hardness, heat resistance, and wear resistance of plastic materials, improves impact strength, and reduces production costs. |

Packaging & Delivery

- Packaging: 25 kg per woven bag or paper-plastic compound bag

- Storage: Keep in a cool, dry, and ventilated area; avoid exposure to moisture or direct sunlight

- Shelf Life: 12 months under proper storage conditions

- Shipping: Available by sea, air, or land according to customer requirements

After-Sales Service

- Professional technical support for formulation optimization

- Free sample testing and performance evaluation

- Customization available for talc content, carrier resin, and color

- Quick response to customer feedback and inquiries